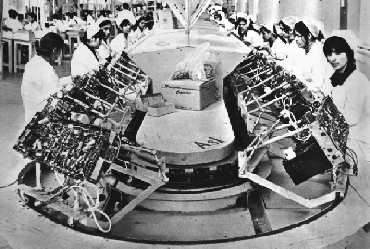

Assembling television sets in a Teheran factory

The industrialization of Iran began early in the Pahlavi era, when Reza Shah set up a number of light industries producing consumer goods. Textiles, silk, processed foods, particularly sugar, tea and tobacco, cement, and building materials were Iran's earliest industrial products. There were more ambitious plans. Our country was actually manufacturing light aircraft and Reza Shah had ordered an integrated steel mill when Iran became engulfed against its will in World War II. Industrialization came to a complete halt, and production at existing factories was seriously impaired by the lack of spare parts and imported raw materials. By the end of World War II, industry in Iran was in a state of total stagnation, and one of the principal objects of the First Plan (1948-55) was to get the factories, which were then almost exclusively State-owned, back into production. But for political and economic reasons it was not until the late 1950's that large-scale industrial investments could be resumed.

The real breakthrough occurred in the immediate aftermath of 1963. Two of the six points of a new programme of the Shah and the government were concerned with industry: The sale of Government factories to finance land reform and the introduction of profit-sharing for industrial workers. Both of these measures, especially the latter, had the effect of revitalizing industry. Business confidence was restored, and the rest of the 1960 saw massive increases in industrial investment, production and productivity. Between 1962 and 1974 the annual rate of industrial growth rose from five per cent to 20 per cent, the contribution of industrial production to GNP increased from 11.7 per cent to about 17 per cent, employment in industry went from 1.3 million to over 2 million, and productivity, in terms of value added per employee, rose by 3 bout 10 per cent annually.

However, by selling factory shares to the private sector the Government did not leave the industrial scene entirely. The policy was rather to encourage private industrialists to invest in the manufacture of consumer goods, while the public sector invested in larger units, such as oil, heavy metallurgy and engineering petrochemicals, pulp and paper, and electronics, fields which were either too big to attract private investment or where precious natural resources were involved. While primary industries such as oil, steel, aluminium and copper smelting remained in the public sector, private industrialists, both domestic and foreign, were encouraged to participate in down-stream operations. Foreign participation was also encouraged in joint ventures with State corporations when advanced technology or the need for large-scale overseas marketing was needed, particularly in the petrochemical field and overseas marketing.

Through a strict system of licensing the Government gave considerable help to infant industries, providing approved projects with subsidized utilities and infrastructure, export incentives, credit facilities and liberal tax laws. As these industries matured, stricter standardization and price control meaures lifted, both to protect domestic consumers and ensure that Iranian manufacturers could efficiently compete in the world market-place. Although high personal profits ensured buoyant markets for domestic industrialists, it wasconsidered essential for Iranian goods to be internationally competitive in order to provide a source of foreign exchange as a long-term substitute for oil revenues

The industrialization strategy was to continue obtaining modern plant, raw materials and components from the industrialized countries while expanding the base of domestic industry by emphasizing on "thrust" areas, which include metal smelting (iron and steel, copper and aluminum), the manufacture of machinery and equipment, and the furthering of electrical, electronics, chemical, petrochemical industries. This strategy aimed at making Iran practically self-sufficient in durable and non-durable goods and building materials, with additional export capacity to finance further expansion.

As an example of current achievement in the seventies, Iran's automotive industry, not yet a decade old, already obtained a sizeable part of its components (including engines, batteries, radiators, shock absorbers, filters, rings, fenders, windshields and other glass parts, tyres, ball bearings, spark plugs and springs) from domestic sources, while new projects would have before long eliminated the need to import the remaining components.

The range of industrial projects being implemented or already commissioned in the seventies is too great to be more than cursorily examined in this survey. The vital oil, gas and petrochemical industries are dealt with in separate chapters, and Table 7 in the Statistical Appendix shows how the production of selected manufactured goods grew the time. Mention may be made, however, of the operations and plans of two Government corporations, National Iranian Steel Co. (NISCO), operator of the National Steel Complex, the annual capacity of which by 1977 reached 1.9 million tons of structural steel items, and National Iranian Steel Industries Co. (NISIC), which planned a new $1 billion project to construct yet another intergrated steelworks near Isfahan, using the new direct reduction process, with a 1.2 million ton capacity. Work had also started on another NISIC steel mill near Bandar Abbas. With other projects at the planning stage, it was envisaged that by 1982, Iran's steel production capacity would have reach ed 15 million tons. In the 1976-77 Budget, metallurgical projects were allocated $430 million, almost one third of the total for industry.

No discussion of the industrial scene in Iran is complete without reference to the ownership structure. Despite efforts in the 1960's to broaden the base of industrial shareholding, until recently most factories were still owned by family groups. At this point the Shah advised the business community to divest itself voluntarily of between one-third and half their shares, first to their own workers and staff and subsequently to the public at large. Some 40 companies were implementing this programme when early in 1975 the government ordered the process speeded up. This action caused the discontent of many industrialists which considered this action as a step towards socialism. A new law was enacted calling for an initial 45 per cent share distribution by 320 large companies over a three-year period. Another feature of the law was that the Government would sell 99 per cent of its holding in certain industries to the public, thus limiting its own industrial involvement to a few basic areas. The importance of this new trend in the shareholding in Iranian industry was underlined when the Shah proclaimed the programme the 13th Principle of the Revolution.